- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

-

Plate sleeveLeveraging Auclean's nearly 30 years of technological expertise and extensive practical experience in the sleeve field, the sleeveX™ brand was born. The SleeveX™ mounting sleeve is crafted from aerospace-grade aramid honeycomb core material, combined with the proprietary FiberP™ inner liner technology, and manufactured through high-precision automated winding processes. The product features impact-absorbing surfaces and full-end sealing structures, enhancing durability and operational safety while improving performance. Additionally, SleeveX™ technology achieves a systematic reconfiguration of materials, structure, process, and user experience, endowing the product with systematic value. Ultra-Thin X-MUT · Structure: High-elasticity GFRP thin-wall structure, improving durability and stability. · Surface hardness: Shore D 90, solid surface hardness, scratch-resistant. · Conductive (option): Rg<1×106Ω, Effectively prevents static buildup from interfering with print quality. · Typical applications: Scenarios where the printing circumference is close to the mandrel; maintain printing accuracy without replacing with a smaller mandrel. (Remarks: Thin wall, smoother on-press mounting; not easy to produce scoring lines, suitable for operating conditions that pursue efficiency and reduced changeover costs.) Thin Type X-MTT · Structure: Multi-layer composite structure (MCS), strengthening impact resistance and overall strength. · Surface hardness: Shore D 82 , wear-resistant and durable. · Conductive (option): Rg<1×106Ω, Effectively prevents static buildup from interfering…View More

Plate sleeveLeveraging Auclean's nearly 30 years of technological expertise and extensive practical experience in the sleeve field, the sleeveX™ brand was born. The SleeveX™ mounting sleeve is crafted from aerospace-grade aramid honeycomb core material, combined with the proprietary FiberP™ inner liner technology, and manufactured through high-precision automated winding processes. The product features impact-absorbing surfaces and full-end sealing structures, enhancing durability and operational safety while improving performance. Additionally, SleeveX™ technology achieves a systematic reconfiguration of materials, structure, process, and user experience, endowing the product with systematic value. Ultra-Thin X-MUT · Structure: High-elasticity GFRP thin-wall structure, improving durability and stability. · Surface hardness: Shore D 90, solid surface hardness, scratch-resistant. · Conductive (option): Rg<1×106Ω, Effectively prevents static buildup from interfering with print quality. · Typical applications: Scenarios where the printing circumference is close to the mandrel; maintain printing accuracy without replacing with a smaller mandrel. (Remarks: Thin wall, smoother on-press mounting; not easy to produce scoring lines, suitable for operating conditions that pursue efficiency and reduced changeover costs.) Thin Type X-MTT · Structure: Multi-layer composite structure (MCS), strengthening impact resistance and overall strength. · Surface hardness: Shore D 82 , wear-resistant and durable. · Conductive (option): Rg<1×106Ω, Effectively prevents static buildup from interfering…View More -

Carbon fiber bridge adapterThe material characteristics and structure of carbon fiber bridge make them significantly superior to traditional products in terms of strength, vibration reduction, stability, and service life. For carbon fiber bridge with larger wall thickness, they have significant advantages in reducing weight and printing runout, which can maximize printing performance and are particularly suitable for high-speed and high-precision printing.View More

Carbon fiber bridge adapterThe material characteristics and structure of carbon fiber bridge make them significantly superior to traditional products in terms of strength, vibration reduction, stability, and service life. For carbon fiber bridge with larger wall thickness, they have significant advantages in reducing weight and printing runout, which can maximize printing performance and are particularly suitable for high-speed and high-precision printing.View More -

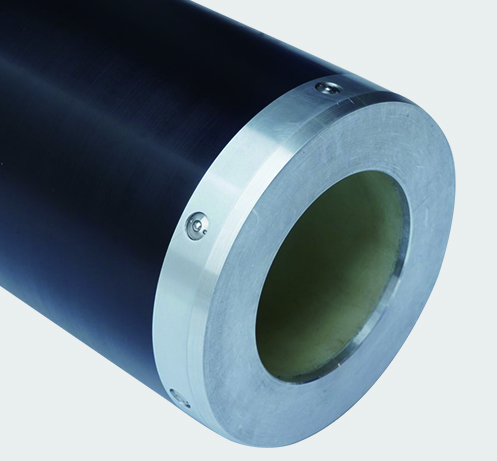

Base sleeveThe special fiberglass material FiberP™ is suitable for the encapsulation production of rubber sleeves. Its rough surface is conducive to enhancing the adhesion of rubber, and it can withstand vulcanization temperatures up to 140 ° C. We provide OEM flexographic and gravure base sleeves, as well as conductive base sleeves (Rg < 1×106Ω) according to customer specifications.View More

Base sleeveThe special fiberglass material FiberP™ is suitable for the encapsulation production of rubber sleeves. Its rough surface is conducive to enhancing the adhesion of rubber, and it can withstand vulcanization temperatures up to 140 ° C. We provide OEM flexographic and gravure base sleeves, as well as conductive base sleeves (Rg < 1×106Ω) according to customer specifications.View More -

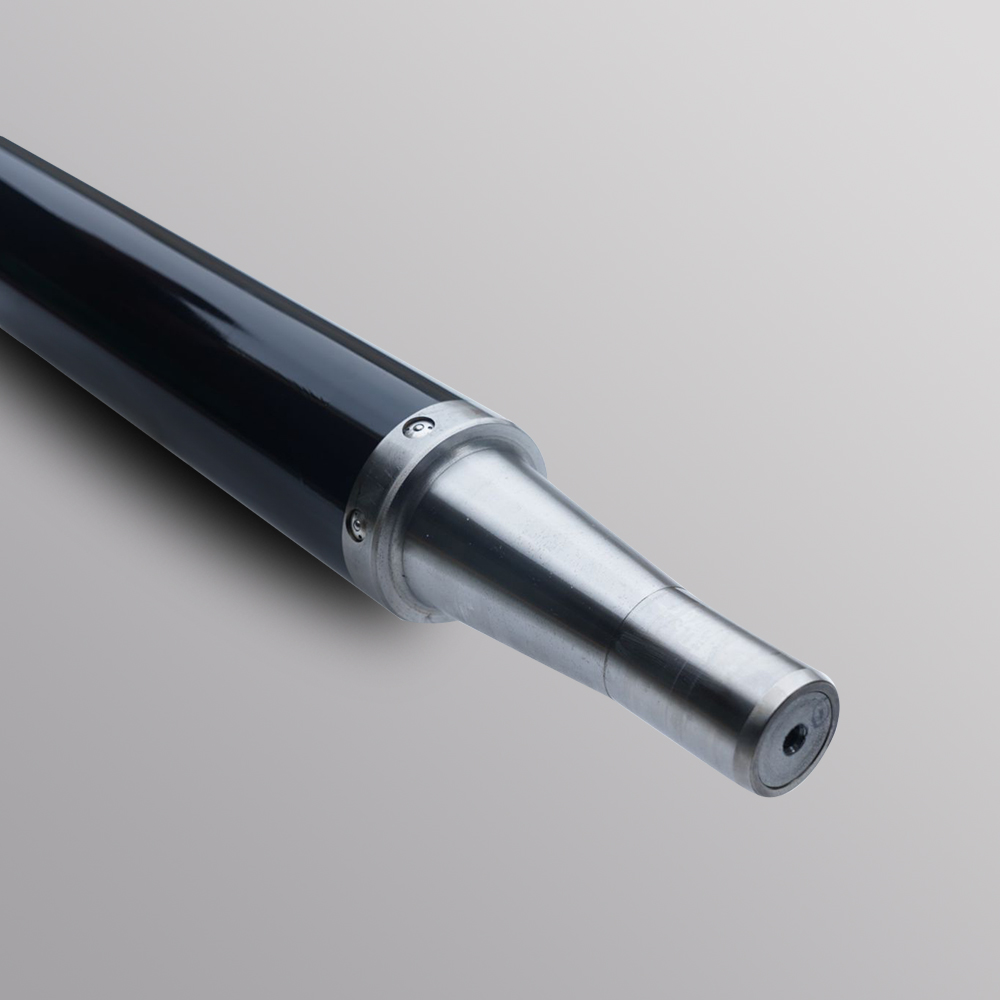

Air shaftThis product is designed specifically for sleeve systems. Using high-quality steel, after heat treatment and precision manufacturing, the roller surface is hard chrome plated; Adopting the Mira valve ventilation design, only a small amount of air flow is required for loading and unloading the sleeve. We can provide OEM services for equipment manufacturers, or customize mandrel fixtures according to customers' air shaft specifications.View More

Air shaftThis product is designed specifically for sleeve systems. Using high-quality steel, after heat treatment and precision manufacturing, the roller surface is hard chrome plated; Adopting the Mira valve ventilation design, only a small amount of air flow is required for loading and unloading the sleeve. We can provide OEM services for equipment manufacturers, or customize mandrel fixtures according to customers' air shaft specifications.View More -

Carbon fiber air shaft• Cooperate with high-speed printing speed to greatly reduce the vibration caused by high speed; • Excellent overload performance, matched with wide-web and large-sized bridge sleeves; • Corrosion resistance, chemical solvent resistance, and strong adaptability to working conditions; • High critical speed can double the printing speed; • High rigidity, low deflection, low coefficient of expansion, and small deformation; • Compared to traditional steel, it can reduce weight; • High modulus carbon fiber structure design ensures printing stability.View More

Carbon fiber air shaft• Cooperate with high-speed printing speed to greatly reduce the vibration caused by high speed; • Excellent overload performance, matched with wide-web and large-sized bridge sleeves; • Corrosion resistance, chemical solvent resistance, and strong adaptability to working conditions; • High critical speed can double the printing speed; • High rigidity, low deflection, low coefficient of expansion, and small deformation; • Compared to traditional steel, it can reduce weight; • High modulus carbon fiber structure design ensures printing stability.View More -

Wide-web sleeve loading and unloading seatSuitable for air shafts. The width of the sleeve can reach 3000mm/118inch, and the outer diameter of the sleeve is not limited; Only clean and dry compressed air at 0.6~0.8Mpa/6~8 bar is needed; Easy to operate, sturdy in structure, and small in footprint, it is an essential specialized tool for loading and unloading sleeves. (Customized according to the customer's specifications for the air shaft head)View More

Wide-web sleeve loading and unloading seatSuitable for air shafts. The width of the sleeve can reach 3000mm/118inch, and the outer diameter of the sleeve is not limited; Only clean and dry compressed air at 0.6~0.8Mpa/6~8 bar is needed; Easy to operate, sturdy in structure, and small in footprint, it is an essential specialized tool for loading and unloading sleeves. (Customized according to the customer's specifications for the air shaft head)View More -

Narrow-web sleeve loading and unloading seatSuitable for air shaft. The sleeve width is 820mm/32inch, and only requires clean and dry compressed air at 0.6~0.8Mpa/6~8 bar. Adopting a desktop design, it saves space, is easy to use. Its sturdy structure and small footprint make it an indispensable specialized tool for loading and unloading sleeves. (Can be customized according to the customer's inflatable core specifications)View More

Narrow-web sleeve loading and unloading seatSuitable for air shaft. The sleeve width is 820mm/32inch, and only requires clean and dry compressed air at 0.6~0.8Mpa/6~8 bar. Adopting a desktop design, it saves space, is easy to use. Its sturdy structure and small footprint make it an indispensable specialized tool for loading and unloading sleeves. (Can be customized according to the customer's inflatable core specifications)View More -

Sleeve storage and transportation trolley (sTrolley)STrolley can be regarded as a sleeve mobile library, achieving the integration of sleeve storage and transportation. Vertical storage design avoids sleeve deformation; The cushion layer protects the sleeve end; The anti shake patent (patent number: ZL 2022 2 2268042.6) design during its transportation ensures safety and reliability, and the ergonomic design makes it convenient and effortless to insert and remove the sleeve. Featuring a heavy-duty steel structure, silent and labor-saving double bearing rubber wheels, anti displacement locking casters, and A4 paper inserts for easy record management. Suitable for all sleeve specifications. STrolley 9060-8 type: with a maximum outer diameter of 140mm, it can store 8 units; STrolley 10563-8 type: with a maximum outer diameter of 180mm, it can store 8 units; STrolley 12670-8 type: with a maximum outer diameter of 230mm, it can store 8 units; STrolley 15080-8 type: with a maximum outer diameter of 290mm, it can store 8 units; STrolley 150100-6 type: with a maximum outer diameter of 400mm, it can store 6 units.View More

Sleeve storage and transportation trolley (sTrolley)STrolley can be regarded as a sleeve mobile library, achieving the integration of sleeve storage and transportation. Vertical storage design avoids sleeve deformation; The cushion layer protects the sleeve end; The anti shake patent (patent number: ZL 2022 2 2268042.6) design during its transportation ensures safety and reliability, and the ergonomic design makes it convenient and effortless to insert and remove the sleeve. Featuring a heavy-duty steel structure, silent and labor-saving double bearing rubber wheels, anti displacement locking casters, and A4 paper inserts for easy record management. Suitable for all sleeve specifications. STrolley 9060-8 type: with a maximum outer diameter of 140mm, it can store 8 units; STrolley 10563-8 type: with a maximum outer diameter of 180mm, it can store 8 units; STrolley 12670-8 type: with a maximum outer diameter of 230mm, it can store 8 units; STrolley 15080-8 type: with a maximum outer diameter of 290mm, it can store 8 units; STrolley 150100-6 type: with a maximum outer diameter of 400mm, it can store 6 units.View More