- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

Plate sleeve

Leveraging Auclean’s nearly 30 years of technological expertise and extensive practical experience in the sleeve field, the sleeveX™ brand was born.

The SleeveX™ mounting sleeve is crafted from aerospace-grade aramid honeycomb core material, combined with the proprietary FiberP™ inner liner technology, and manufactured through high-precision automated winding processes. The product features impact-absorbing surfaces and full-end sealing structures, enhancing durability and operational safety while improving performance. Additionally, SleeveX™ technology achieves a systematic reconfiguration of materials, structure, process, and user experience, endowing the product with systematic value.

Ultra-Thin X-MUT

· Structure: High-elasticity GFRP thin-wall structure, improving durability and stability.

· Surface hardness: Shore D 90, solid surface hardness, scratch-resistant.

· Conductive (option): Rg<1×106Ω, Effectively prevents static buildup from interfering with print quality.

· Typical applications: Scenarios where the printing circumference is close to the mandrel; maintain printing accuracy without replacing with a smaller mandrel.

(Remarks: Thin wall, smoother on-press mounting; not easy to produce scoring lines, suitable for operating conditions that pursue efficiency and reduced changeover costs.)

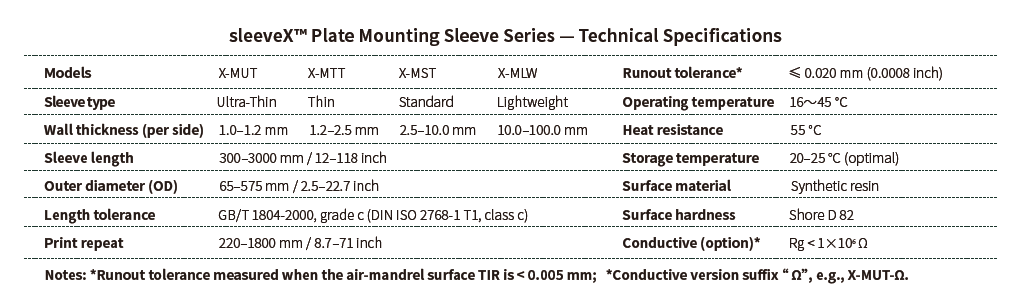

Thin Type X-MTT

· Structure: Multi-layer composite structure (MCS), strengthening impact resistance and overall strength.

· Surface hardness: Shore D 82 , wear-resistant and durable.

· Conductive (option): Rg<1×106Ω, Effectively prevents static buildup from interfering with print quality.

· Typical applications: Mid- to high-end jobs and high-speed, high-load equipment, remaining stable in long-term operation.

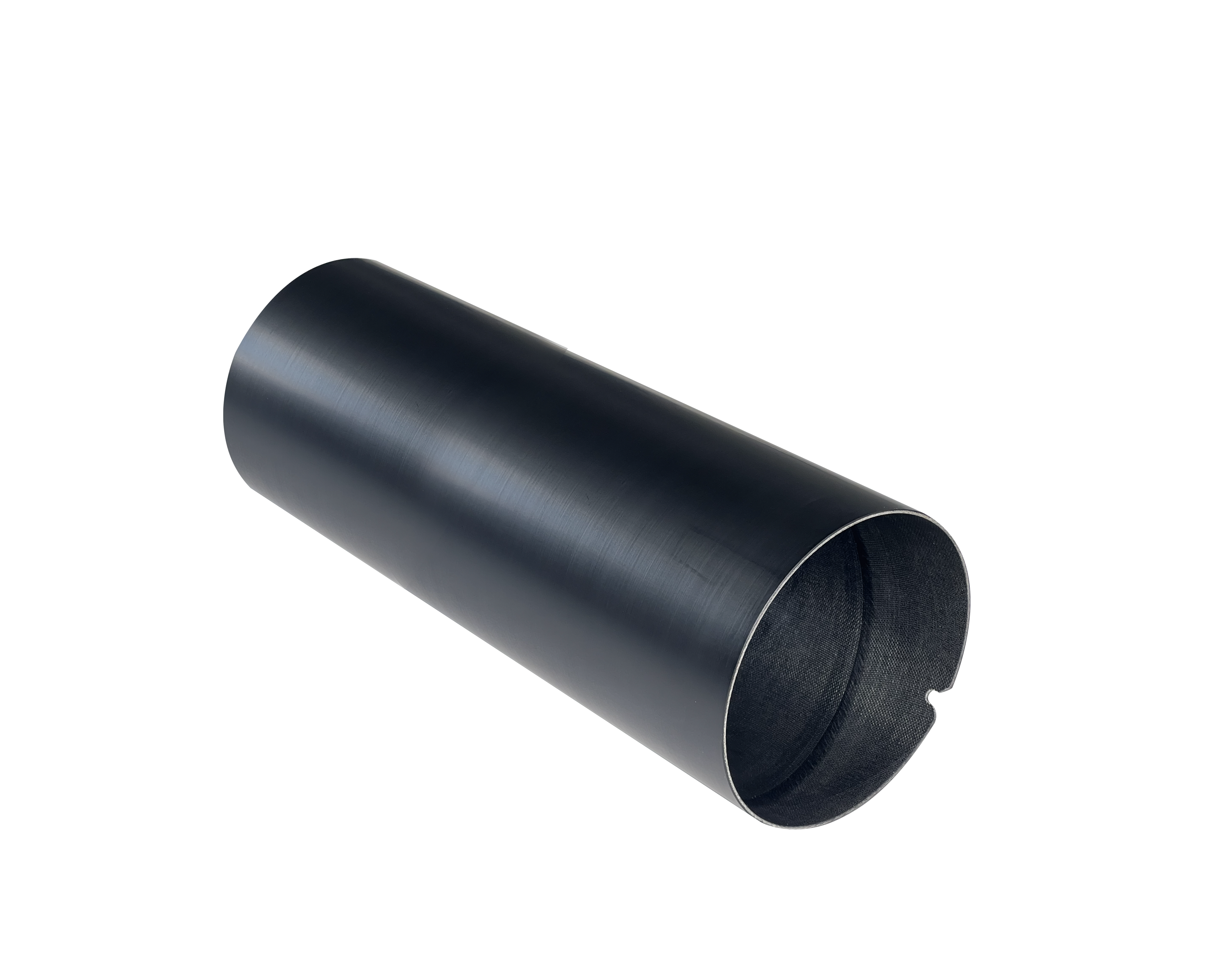

Standard Type X-MST

· Structure: Multi-layer composite“ snowflake-sheet” (MCSS) structure, providing higher impact resistance and durability.

· Surface hardness: Shore D 82 , for long service life and wear resistance.

· Conductive (option): Rg<1×106Ω, Effectively prevents static buildup from interfering with print quality.

· Typical applications: Broad general-purpose coverage, fitting high-load and multi-shift production.

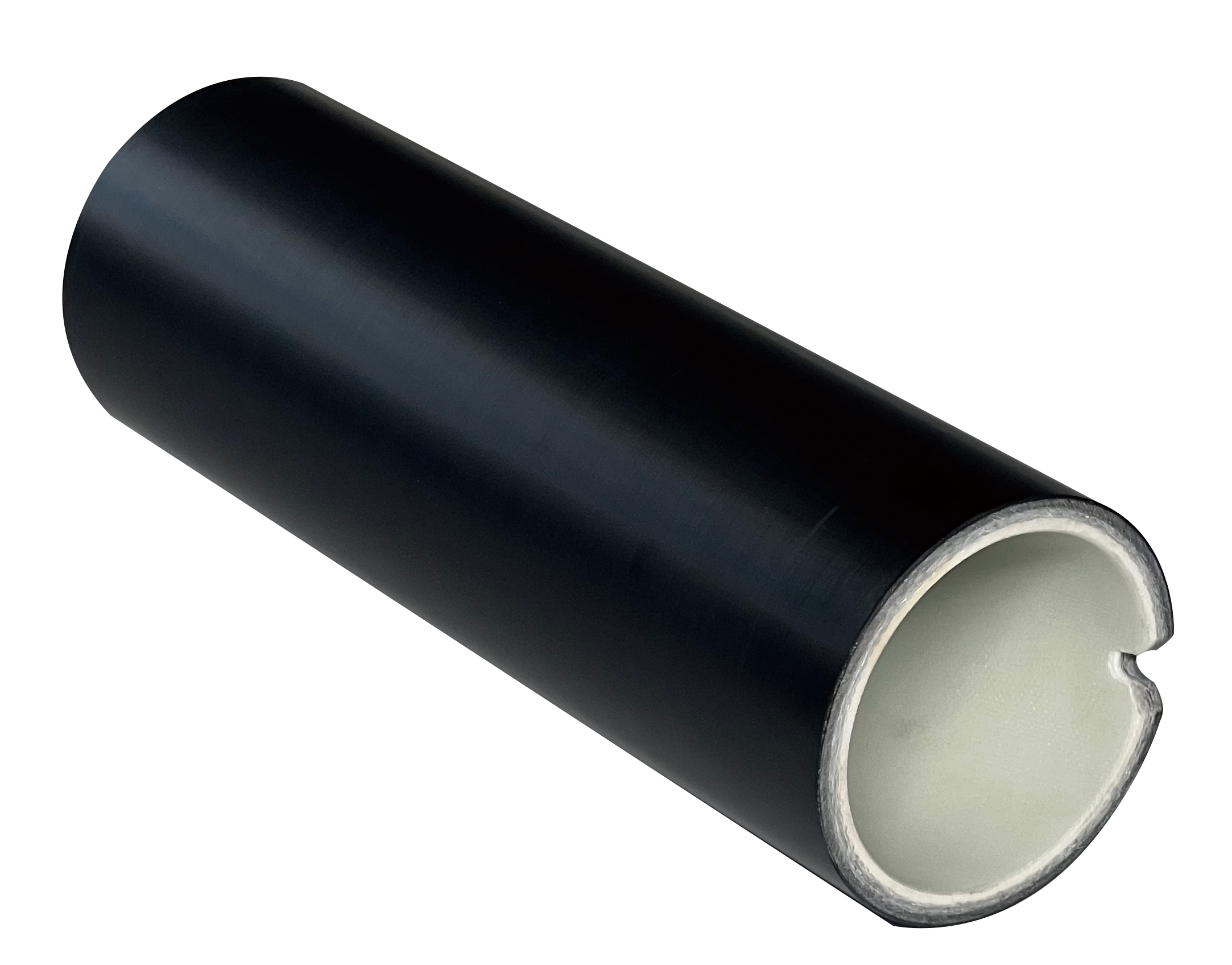

Lightweight X-MLW

· Structure: Aerospace-grade honeycomb core + Buffer-Impact Shield™ end-face protection + full-end sealing multi-layer composite structure; giving equal weight to lightweight design and service life.

· Surface hardness: Shore D 82 , durably wear-resistant.

· Conductive (option): Rg<1×106Ω, Effectively prevents static buildup from interfering with print quality.

· Typical applications: High-speed/high-load printing; supports configurations with single-side wall thickness up to 100 mm, reducing the number of bridge-sleeve specifications.